In September 2022 a laser cutting robot with an impressive reach of 1.8 metres was put into operation. This freely programmable system is characterised by its ability to precisely burn 5-axis holes in stainless steel with a thickness of up to 4 mm. Four carefully trained employees were appointed to operate this technological achievement. The system is used for the standard production of 4 000 swivel arms per year and also opens up innovative possibilities in the field of conveyor technology.

An automatic welding system that works with plasma and TIG processes was implemented in March 2023. This highly developed system is capable of welding X-ray-safe circumferential and longitudinal seams of up to 3.5 metres in diameter and length with wall thicknesses of up to 12 mm. Under the careful supervision of three experienced welding experts, the doubling of the welding speed leads to a considerable time saving of up to 75 percent per job and at the same time increases the overall efficiency of the production process.

In the summer of 2023, technological development at BUTTING China reached a milestone with the introduction of an orbital welding machine. This system is equipped with an EWM unit and enables the welding of circumferential seams for dimensions ranging from 1/2" to 6" with wall thicknesses of up to 4 mm. Three additionally trained specialists were deployed to operate this advanced equipment.

BUTTING China pursues a strategy based on sustainable business practices and responsible resource management. This includes increasing efficiency in production and the material flow, enhancing process reliability and continuously improving working conditions for Chinese colleagues. In terms of sustainability and in line with BUTTING's corporate values, it is important to Jens Ellermann to ensure, in China too, pleasant and ergonomic working conditions and a high level of attractiveness of BUTTING as an employer. Targeted measures for competitiveness and adaptability are an essential part of sustainability. Only in this way can BUTTING China successfully meet the current challenges, including those posed by a changing industrial landscape, and fulfil its responsibilities.

BUTTING – more than pipes – for a better quality of life

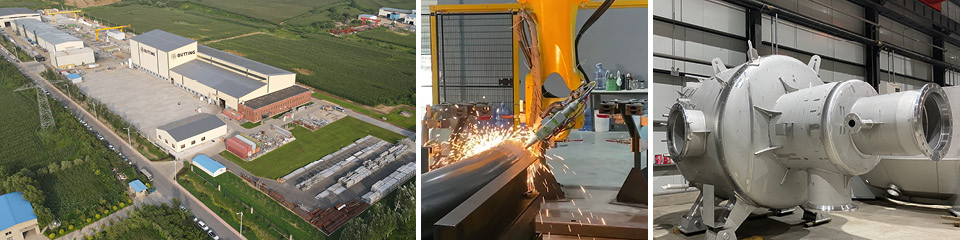

BUTTING China: Top performance in stainless steel processing